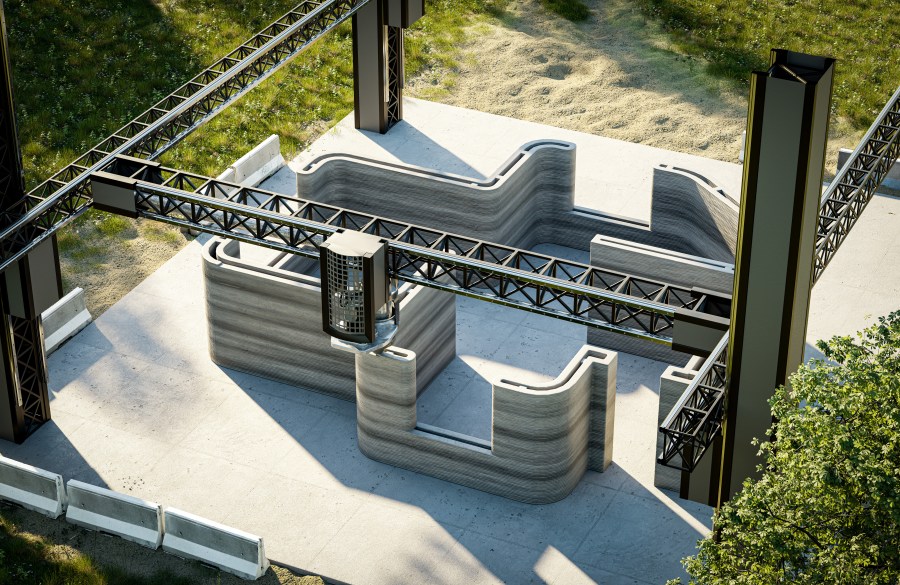

HONOLULU (KHON2) — A machine pours concrete like soft-serve ice cream. Walls rise, layer by layer, as if built by a robot from a sci-fi movie. This is not the future. it’s happening now.

From small homes in Mexico to a Starbucks in Texas, 3D printing is starting to change how buildings are made.

The impact will be big: on jobs, safety, costs and even how fast you can move into a new house. But the road ahead has bumps and plenty of questions still need answering.

If you’ve ever wondered how 3D-printed homes could change the world around you — including the cost of living, who gets hired and how safe a printed house really is — here’s what you need to know.

1. It’s not just about houses anymore

3D printing in construction started with homes, but it’s spreading fast. In Brownsville, Texas, the Associated Press reported that Starbucks just opened its first 3D-printed store in the U.S.

A robotic arm laid the walls, which now stand ridged and gray like stacked ropes of clay. It’s drive-thru only, but that’s not the point. What matters is that big companies are beginning to trust the tech. That signals something larger: the move from experiments to real-world use.

2. The process looks like frosting a cake, but it’s concrete

The machines don’t look like builders. They’re long, boxy robots with hoses that squeeze out concrete in smooth loops. Each loop stacks on the last and builds walls right on the spot.

These machines can keep going all day and night without lunch or bathroom breaks or smoke time. The Associated Press reported that some houses in Mexico were printed in just 24 hours.

But that’s just the walls. Roofs, wiring and windows still need people to install them.

3. Jobs will change, not just disappear

3D printing doesn’t erase the need for people. But will change what they do. Instead of lifting bricks or sawing beams, workers might program printers, test materials, or fix glitches in digital plans.

Laborers who once worked outdoors in the heat may move indoors to monitor machines. But there’s a catch: not everyone will have the skills right away. New training and new careers will be needed. And for some, especially those in low-skill, high-risk jobs, work may become harder to find.

Hence, it’s imperative that we educate our keiki and adults in science and tech. This will prevent Hawaiʻi’s workforce from being left behind as work dwindles in traditional trades.

4. Labor shortages make this tech more appealing

In places like the U.S., Singapore and Qatar, construction depends heavily on migrant workers. But workers are in short supply. In the U.S., many skilled laborers are aging out of the workforce; and younger people are choosing different careers.

In Qatar, massive building projects for the World Cup were delayed because of visa crackdowns. When builders can’t find enough people, machines become more attractive. That’s where 3D printing steps in.

5. Not every building can be printed (yet)

Most 3D printers used in construction today are limited to small or single-story buildings. For taller structures, like the five-story apartment printed in China, builders still have to mix in traditional methods.

Reinforced steel, plumbing, glass windows and roofing aren’t printed. The same goes for interior finishes like cabinets or air conditioning. Think of it like this: the printer lays the skeleton, but the rest still needs human hands, for now.

6. Regulation is lagging behind the technology

In many places, 3D-printed buildings aren’t yet covered by building codes. That means each project often needs special approval. Without clear rules, it’s harder to know who’s responsible if something goes wrong.

Some researchers indicate that this gap slows down progress and adds risk. In the U.S., organizations are working to catch up; but until the codes are updated, we can expect more red tape than ribbon-cuttings.

7. It’s not always cheaper, but it can be faster

Building a 3D printer is expensive. So are the engineers who run it. In some cases, this makes the total cost higher than traditional wood framing. But over time, the numbers are expected to shift.

Already, builders are indicating that 3D printing can cut labor costs by up to 80% and construction time by more than half. In Colorado, factory-built homes are being completed in as little as five days on the assembly line. Time is money, and faster building often means lower prices down the line.

8. These homes may help fight the housing crisis

In Hawai‘i, the high cost of housing is an bit issue; and it’s a crisis that touches nearly every community. From teachers in Hilo to health care workers on Maui, many local residents can’t afford to live near their jobs.

The need for affordable housing is urgent; but traditional construction methods are often too slow, expensive or tied up in red tape.

3D-printed and modular homes could offer part of the solution. These structures are faster to build and potentially less expensive to produce at scale. In places like Eagle, Colorado, this resort town has its own housing squeeze and decided to utilize printed homes to house essential workers. In Mexico, entire neighborhoods have been created in a matter of days.

Hawai‘i could follow suit, especially on Department of Hawaiian Homelands parcels or other state-owned lands where cost and timing are critical.

These aren’t cookie-cutter solutions, and they’d need to reflect Hawai‘i’s culture, climate and construction codes. But they may offer a faster way to put roofs over local heads and keep more families rooted in their home communities.

9. New materials are changing the game

Concrete isn’t the only option. Builders are experimenting with materials like hempcrete. That’s a mix of hemp and lime, and it acts as insulation and an outer wall all in one. Hempcrete is mold-resistant, fire-resistant and grows in months instead of decades.

Though it still needs a wooden frame, researchers are working on ways to print it without any extra support. As materials improve, printed buildings may get safer, greener and cheaper.

10. This tech won’t replace people; it’ll work alongside them

Some worry that robots will take over the job site. But the reality is more complex. New technologies from drones to 3D printers are changing construction rather than erasing it.

Workers are still needed but in different roles. And 3D printing can make dangerous jobs safer by keeping people out of risky environments. It’s a shift, not a shutdown.

3D-printed construction is no longer a wild idea. It’s showing up in neighborhoods, coffee shops and housing projects. The benefits are clear: faster builds, less waste, fewer injuries.

But challenges remain. The technology still needs time to mature, and the rules that govern building safety must evolve with it. Meanwhile, the construction industry faces tough questions about jobs, costs and who gets left behind.

You can click here to read a study on the impacts 3D printing will have on the construction industry.

What’s certain is this: the walls of tomorrow are already rising. Whether poured by hand or printed by robot, how we build is changing; and it’s happening faster than many expected.